Welcome to the official website of Guizhou Fulaimei Drilling Equipment Co., Ltd!

Contact Phone:13968981314

Cone

Product Classification:

Product Introduction

The cone bit uses the rotation of the cone (or gear) to break the rock and achieve the purpose of drilling. It is mainly composed of drill body, cone, bearing and nozzle. According to different uses and models, it may also contain auxiliary parts such as sealing and bearing lubrication. Roller bit plays an important role in petroleum, geological drilling and various geotechnical engineering fields.

Cone bit is widely used in oil drilling, geological exploration, geotechnical engineering, building foundation construction and other fields. In the gravel layer and limestone formation, the cone bit has high drilling efficiency and good well quality, which can greatly reduce the construction drilling cost.

| drill bit parameters | |||

| Bit size (In) | 8-1/2'' | 9-1/2'' | 12-1/4'' |

| Bit size (mm) | 215.9 | 241.3 | 311.1 |

| IADC coding | 437 | 437 | 437 |

| Connecting buckle type | 4-1/2 ''APIREG | 6-5/8 ''APIREG | 6-5/8 ''APIREG |

| recommend speed | 240~70 | 240~70 | 240~70 |

| recommend weight on bit | 0.35~0.9 | 0.35~0.9 | 0.35~0.9 |

| Product Features |

◆ Suitable for low compressive strength, high drillability of extremely soft strata, clay, mudstone, gypsum, soft stone, limestone...;

◆ Wear-resistant coating, carbide wear-resistant material is applied to the tip of the palm and the edge of the tooth palm to increase the wear resistance of the drill bit;

◆ Carbide righting block is embedded in the surface of the tooth palm to reduce the wear of the drill bit in grinding formation, inclined well and horizontal well, and improve the service life of the drill bit;

◆ High-quality tungsten carbide alloy gauge teeth reduce the wear of the drill bit in the grinding formation and improve the stability and service life of the drill bit;

The high quality tungsten carbide alloy tooth, reduce wear and increase the crushing ability of the drill life;

◆ Optimize the hydraulic structure and enhance the service life of the drill bit self-washing ability.

| drill bit parameters | |||

| Bit size (In) | 8-1/2'' | 9-1/2'' | 17-1/2'' |

| Bit size (mm) | 215.9 | 241.3 | 444.5 |

| IADC coding | 517 | 517 | 517 |

| Connecting buckle type | 4-1/2 ''APIREG | 6-5/8 ''APIREG | 7-5/8 ''APIREG |

| recommend speed | 220~60 | 220~60 | 220~60 |

| recommend weight on bit | 0.35~1.0 | 0.35~1.0 | 0.35~1.0 |

| Product Features |

◆ Suitable for low compressive strength, high drillability of extremely soft strata, mudstone, gypsum, salt rock, soft stone, limestone...;

◆ Wear-resistant coating, carbide wear-resistant material is applied to the tip of the palm and the edge of the tooth palm to increase the wear resistance of the drill bit;

◆ Carbide righting block is embedded in the surface of the tooth palm to reduce the wear of the drill bit in grinding formation, inclined well and horizontal well, and improve the service life of the drill bit;

◆ High-quality tungsten carbide alloy gauge teeth reduce the wear of the drill bit in the grinding formation and improve the stability and service life of the drill bit;

The high quality tungsten carbide alloy tooth, reduce wear and increase the crushing ability of the drill life;

◆ Optimize the hydraulic structure and enhance the service life of the drill bit self-washing ability.

| drill bit parameters | |||

| Bit size (In) | 8-1/2'' | 9-1/2'' | 12-1/2'' |

| Bit size (mm) | 215.9 | 241.3 | 311.1 |

| IADC coding | 537 | 537 | 537 |

| Connecting buckle type | 4-1/2 ''APIREG | 6-5/8 ''APIREG | 6-5/8 ''APIREG |

| recommend speed | 220~50 | 220~50 | 220~50 |

| recommend weight on bit | 0.45~1.0 | 0.45~1.0 | 0.45~1.0 |

| Product Features |

◆ Suitable for soft to medium hard formations with low compressive strength, shale, limestone, sandstone, medium hard formations with high abrasive interlayers...;

◆ Wear-resistant coating, carbide wear-resistant material is applied to the tip of the palm and the edge of the tooth palm to increase the wear resistance of the drill bit;

The six-point stabilization system makes the cone bit contact with the borehole wall through six force points, improving the stability of the bit and protecting the integrity of the cutting tooth structure;

◆ High-quality tungsten carbide alloy gauge teeth reduce the wear of the drill bit in the grinding formation and improve the stability and service life of the drill bit;

The high quality tungsten carbide alloy tooth, reduce wear and increase the crushing ability of the drill life;

◆ Optimize the hydraulic structure and enhance the service life of the drill bit self-washing ability.

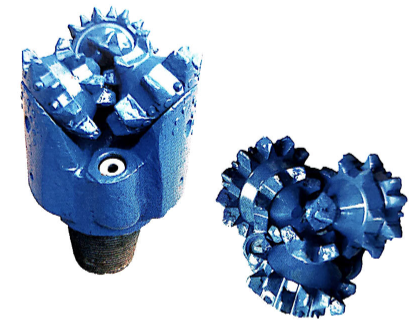

| drill bit parameters | |||

| Bit size (In) | 8-1/2'' | 9-1/2'' | 17-1/2'' |

| Bit size (mm) | 215.9 | 241.3 | 444.5 |

| IADC coding | 617 | 617 | 617 |

| Connecting buckle type | 4-1/2 ''APIREG | 6-5/8 ''APIREG | 7-5/8 ''APIREG |

| recommend speed | 200~50 | 200~50 | 200~50 |

| recommend weight on bit | 0.45~1.1 | 0.45~1.1 | 0.45~1.1 |

| Product Features |

◆ Suitable for medium-hard strata with high compressive strength, hard shale limestone sandstone dolomite...;

◆ Wear-resistant coating, carbide wear-resistant material is applied to the tip of the palm and the edge of the tooth palm to increase the wear resistance of the drill bit;

The six-point stabilization system makes the cone bit contact with the borehole wall through six force points, improving the stability of the bit and protecting the integrity of the cutting tooth structure;

◆ High-quality tungsten carbide alloy gauge teeth reduce the wear of the drill bit in the grinding formation and improve the stability and service life of the drill bit;

The high quality tungsten carbide alloy tooth, reduce wear and increase the crushing ability of the drill life;

◆ Optimize the hydraulic structure and enhance the service life of the drill bit self-washing ability.

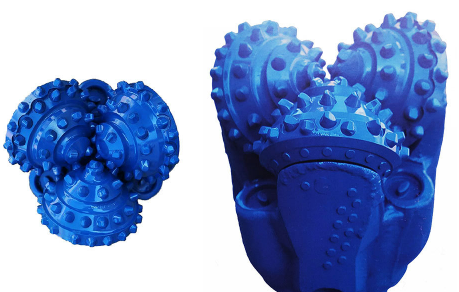

| drill bit parameters | |||

| Bit size (In) | 8-1/2'' | 9-1/2'' | 17-1/2'' |

| Bit size (mm) | 215.9 | 241.3 | 444.5 |

| IADC coding | 637 | 637 | 637 |

| Connecting buckle type | 4-1/2 ''APIREG | 6-5/8 ''APIREG | 7-5/8 ''APIREG |

| recommend speed | 180~40 | 180~40 | 180~40 |

| recommend weight on bit | 0.5~1.1 | 0.5~1.1 | 0.5~1.1 |

| Product Features |

◆ Suitable for high compressive strength of hard strata, sandstone, limestone, dolomite, anhydrite, marble...;

◆ Wear-resistant coating, carbide wear-resistant material is applied to the tip of the palm and the edge of the tooth palm to increase the wear resistance of the drill bit;

The six-point stabilization system makes the cone bit contact with the borehole wall through six force points, improving the stability of the bit and protecting the integrity of the cutting tooth structure;

◆ High-quality tungsten carbide alloy gauge teeth reduce the wear of the drill bit in the grinding formation and improve the stability and service life of the drill bit;

The high quality tungsten carbide alloy tooth, reduce wear and increase the crushing ability of the drill life;

◆ Optimize the hydraulic structure and enhance the service life of the drill bit self-washing ability.

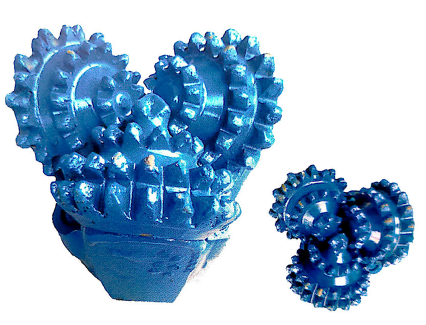

| drill bit parameters | |||

| Bit size (In) | 8-1/2'' | 9-1/2'' | 12-1/2'' |

| Bit size (mm) | 215.9 | 241.3 | 311.1 |

| IADC coding | 637R | 637R | 637R |

| Connecting buckle type | 4-1/2 ''APIREG | 6-5/8 ''APIREG | 6-5/8 ''APIREG |

| recommend speed | 180~40 | 180~40 | 180~40 |

| recommend weight on bit | 0.5~1.1 | 0.5~1.1 | 0.5~1.1 |

| Product Features |

◆ Suitable for high compressive strength, high abrasive extremely hard formation, sandstone, limestone, dolomite, anhydrite, marble...;

◆ Wear-resistant coating, carbide wear-resistant material is applied to the tip of the palm and the edge of the tooth palm to increase the wear resistance of the drill bit;

The six-point stabilization system makes the cone bit contact with the borehole wall through six force points, improving the stability of the bit and protecting the integrity of the cutting tooth structure;

● High-quality tungsten carbide alloy gauge teeth reduce the wear of the drill bit in the grinding formation and improve the stability and service life of the drill bit;

The spherical teeth, with better bending strength, further improve the wear resistance of the drill life;

◆ Optimize the hydraulic structure and enhance the service life of the drill bit self-washing ability.

| drill bit parameters | |||

| IADC coding | 217 | ||

| recommend speed | 150~60 | ||

| recommend weight on bit | 0.35~0.95 | ||

| Product Features |

It is suitable for medium-hard strata with high compressive strength, such as medium-soft shale, anhydrite, medium-soft limestone, medium-soft sandstone and soft strata with hard interlayers.

| drill bit parameters | |||

| IADC coding | 127 | ||

| recommend speed | 180~60 | ||

| recommend weight on bit | 0.3~0.85 | ||

| Product Features |

It is suitable for soft formation with low compressive strength and high drillability, such as mudstone, chalk rock, rock salt, soft limestone, etc.

| drill bit parameters | |||

| IADC coding | 117 | ||

| recommend speed | 180~60 | ||

| recommend weight on bit | 0.3~0.75 | ||

| Product Features |

It is suitable for soft formation with low compressive strength and high drillability, such as mudstone, chalk rock, rock salt, soft limestone, etc.

| drill bit parameters | |||

| IADC coding | 114 | ||

| recommend speed | 180~60 | ||

| recommend weight on bit | 0.35~0.75 | ||

| Product Features |

It is suitable for soft formation with low compressive strength and high drillability, such as mudstone, chalk rock, rock salt, soft limestone, etc.

| drill bit parameters | |||

| IADC coding | 532 | ||

| recommend speed | 110~65 | ||

| recommend weight on bit | 0.5~0.8 | ||

| Product Features |

It is suitable for soft formation with low compressive strength and high drillability, such as mudstone, gypsum, chalk, rock salt, soft limestone, etc.

| drill bit parameters | |||

| IADC coding | 632 | ||

| recommend speed | 100~60 | ||

| recommend weight on bit | 0.5~0.9 | ||

| Product Features |

Suitable for hard strata with hard rock; such as quartz, pyrite, hematite, magnetite, chrome ore, siliceous limestone, phosphate limestone, granite, etc.

Online consultation

Related Products