Welcome to the official website of Guizhou Fulaimei Drilling Equipment Co., Ltd!

Contact Phone:13968981314

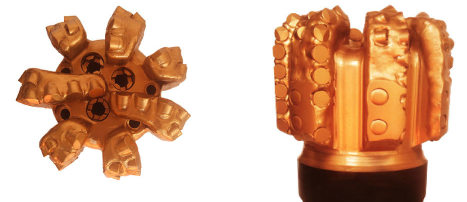

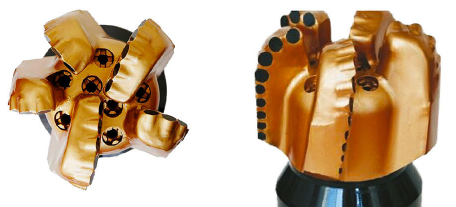

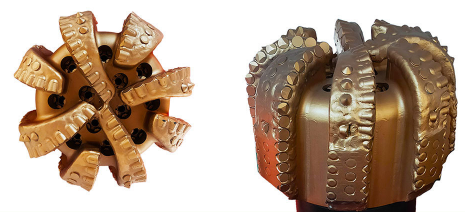

PDC steel body bit

Product Classification:

Product Introduction

PDC steel body drill bits combine the high hardness and wear resistance of polycrystalline diamond (PDC) with the high strength and stability of the steel body. It uses polycrystalline diamond (thin disc) as a cutting block, fixed on the steel body bit body by way of inlay or sintering. PDC steel body bits are mainly used for drilling operations in soft to medium hard formations.

PDC steel drill bits are available in a wide range of sizes, with common drill body diameters ranging from 6 "to 17 1/2" (I. e. 152.4mm to 444.5mm). Specific specifications and models can be customized according to drilling needs.

| drill bit parameters | |

| Dimensions | 6'' |

| Number of blade wings | 4 |

| Main cutting tooth specification | 13 |

| Number of nozzles | 4 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 3-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 20-35 |

| Features: spiral four blade wing four water |

◆ Suitable for soft to medium hard formation, limestone shale sandstone...;

◆ Spiral blade design to enhance blade strength, increase deepening water channel and accelerate sludge discharge.

| drill bit parameters | |

| Dimensions | 6'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 13 |

| Number of nozzles | 5 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 3-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 20-35 |

| Features: single row of teeth, five blade wings and five water eyes |

◆ Suitable for soft to medium hard formation, limestone sandstone shale...;

◆ The surface of the blade is welded with high-performance wear-resistant materials to enhance the wear resistance and erosion resistance of the drill bit;

◆ High-quality composite sheet diameter, reduce diameter wear and increase the wear resistance stability of drill diameter;

◆ Hydraulic structure optimization, bottom hole flow field simulation hydraulic balance design, conducive to the drill bit cleaning cooling mud bag.

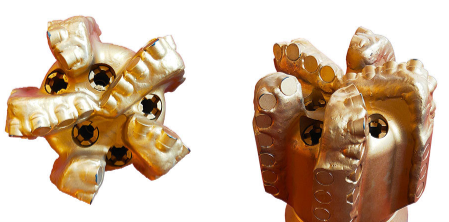

| drill bit parameters | |

| Dimensions | 6'' |

| Number of blade wings | 6 |

| Main cutting tooth specification | 13 |

| Number of nozzles | 6 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 3-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 80-300 |

| Weight on Bit | 10-100 |

| Displacement | 20-35 |

| Features: single row of teeth, six blade wings, seven water eyes |

◆ medium hard strata with high compressive strength and abrasive content, limestone gypsum rock quartz sandstone...;

◆ The surface of the blade is welded with high-performance wear-resistant materials to enhance the wear resistance and erosion resistance of the drill bit;

◆ Short parabolic long outer cone shape structure anti-whirl design, maximize the mechanical drilling speed stability of the drill bit;

◆ Reasonable configuration of high quality PDC composite sheet, optimization of tooth structure to improve the drill's aggressive abrasion resistance;

◆ The inner cone increases the limit tooth design to effectively control the depth of the drill bit into the formation and avoid the early collapse of the composite sheet;

◆ High-quality arc PDC composite sheet diameter, reduce diameter wear and increase the wear resistance stability of diameter;

◆ Hydraulic structure optimization, bottom hole flow field simulation hydraulic balance design, conducive to the drill bit cleaning cooling mud bag.

| drill bit parameters | |

| Dimensions | 6'' |

| Number of blade wings | 8 |

| Main cutting tooth specification | 13 |

| Number of nozzles | 8 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 3-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 20-35 |

| Features: single row of teeth eight blade wing eight water eye |

◆ Suitable for soft to medium hard formation, limestone sandstone shale...;

◆ The surface of the blade is welded with high-performance wear-resistant materials to enhance the wear resistance and erosion resistance of the drill bit;

◆ High-quality composite sheet diameter, reduce diameter wear and increase the wear resistance stability of drill diameter;

◆ Hydraulic structure optimization, bottom hole flow field simulation hydraulic balance design, conducive to the drill bit cleaning cooling mud bag.

| drill bit parameters | |

| Dimensions | 6'' |

| Number of blade wings | 9 |

| Main cutting tooth specification | 13 |

| Number of nozzles | 6 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 3-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 20-35 |

| Features: single row of teeth nine blade wing six water eye |

◆ Suitable for soft to medium hard formation, limestone sandstone shale...;

◆ The surface of the blade is welded with high-performance wear-resistant materials to enhance the wear resistance and erosion resistance of the drill bit;

◆ High-quality composite sheet diameter, reduce diameter wear and increase the wear resistance stability of drill diameter;

◆ Hydraulic structure optimization, bottom hole flow field simulation hydraulic balance design, conducive to the drill bit cleaning cooling mud bag.

| drill bit parameters | |

| Dimensions | 6'' |

| Number of blade wings | 4 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 6 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 3-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 20-35 |

| Features: four knife wing six water eye |

◆ Suitable for medium-soft formation, limestone clay layer shale...;

◆ The layout of 16 water eyes with four blades and wings is conducive to rapid chip removal, reduction of mud bags and effective improvement of drilling speed. Each blade is embedded with a pair of teeth to improve the stability of the drill bit;

◆ High-quality composite sheet diameter, reduce diameter wear and increase the wear resistance of drill diameter ten stability.

| drill bit parameters | |

| Dimensions | 6'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 5 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 3-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 80-300 |

| Weight on Bit | 10-100 |

| Displacement | 20-35 |

| Features: double row teeth five knife wing five water eye |

◆ Medium-hard strata with high compressive strength and abrasiveness, horizontal well section operation, such as mudstone, dolomite, sandstone, etc;

◆ The surface of the blade is welded with high-performance wear-resistant materials to enhance the wear resistance and erosion resistance of the drill bit;

The short parabolic shape structure, maximize the grinding stability of the drill bit;

◆ Reasonable configuration of high quality PDC composite sheet, optimization of tooth structure to improve the drill's aggressive abrasion resistance;

◆ High-quality arc PDC composite sheet diameter, reduce diameter wear and increase the wear resistance stability of diameter;

◆ Hydraulic structure optimization and bottom-hole flow field design are conducive to the migration of rock cuttings and anti-mud bag.

| drill bit parameters | |

| Dimensions | 6'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 5 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 3-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 20-35 |

| Features: single row of roof teeth, five blade wings and five water eyes |

◆ Suitable for soft to medium hard formation, limestone sandstone shale...;

◆ The main cutting tooth adopts roof tooth design to increase the service life of the drill bit's offensive wear resistance and rock breaking ability;

◆ The surface of the blade is welded with high-performance wear-resistant materials to enhance the wear resistance and erosion resistance of the drill bit;

◆ Reasonable configuration of high quality PDC composite sheet, optimization of tooth structure to improve the drill's aggressive abrasion resistance;

◆ High-quality arc PDC composite sheet diameter, reduce diameter wear and increase the wear resistance stability of diameter;

◆ Hydraulic structure optimization and bottom-hole flow field design are conducive to the migration of rock cuttings and anti-mud bag..

| drill bit parameters | |

| Dimensions | 6 1/8'' |

| Number of blade wings | 6 |

| Main cutting tooth specification | 13 |

| Number of nozzles | 6 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 3-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 20-35 |

| Features: triangular teeth, six blades, six water eyes |

◆ Suitable for soft to medium hard formation, limestone shale sandstone...;

The main cutting tooth adopts triangular tooth design to enhance the impact resistance and wear resistance of the drill bit and extend the life of the drill bit;

◆ The second row of shock-absorbing columns widen the blade, shock absorption and anti-wear to ensure the cutting stability of the drill bit, and widen the blade to increase the torque of the drill bit;

◆ High-quality composite sheet diameter, reduce diameter wear and increase the wear resistance stability of drill bit diameter.

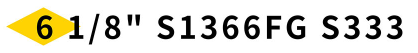

| drill bit parameters | |

| Dimensions | 6 1/8'' |

| Number of blade wings | 6 |

| Main cutting tooth specification | 13 |

| Number of nozzles | 6 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 3-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 20-35 |

| Features: symmetrical six-blade wing limit tooth six water eyes |

◆ suitable for hard strata, chalk shale sandstone...

◆ Symmetrical blade layout, balance the force of the drill bit to increase the stability of the drill bit

◆ The inner cone increases the design of limit teeth to control the depth of the drill bit to eat into the bottom layer to avoid tooth breakage in the early stage of the composite sheet.

| drill bit parameters | |

| Dimensions | 6 1/8'' |

| Number of blade wings | 7 |

| Main cutting tooth specification | 13 |

| Number of nozzles | 7 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 3-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 20-35 |

| Features: double row teeth seven blade wing |

◆ Suitable for soft to medium hard formation, limestone sandstone shale...;

◆ Twelve rows of triangular teeth shock-absorbing columns enhance the impact resistance and wear resistance of the drill bit, prolong the life of the drill bit, and enhance the stability of the drill bit by damping and wear resistance;

◆ High-quality composite sheet diameter, reduce diameter wear and increase the wear resistance stability of drill bit diameter.

| drill bit parameters | |

| Dimensions | 6 1/8'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 5 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 3-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 80-300 |

| Weight on Bit | 10-100 |

| Displacement | 20-35 |

| Features: Axe-shaped teeth Mercedes-Benz teeth five knife wings five water eyes |

◆ suitable for high compressive strength, abrasive medium hard formation, limestone shale sandstone...;

◆ The surface of the blade is welded with high-performance wear-resistant materials to enhance the wear resistance and erosion resistance of the drill bit;

◆ The main cutting teeth are designed with axe-shaped teeth and Mercedes-Benz teeth to balance the cutting ability of the drill bit and enhance the wear resistance of the drill bit against the impact of mechanical drilling speed;

◆ Widen the blade to increase the torque of the drill bit;

◆ Reasonable configuration of high quality PDC composite sheet, optimization of tooth structure to improve the drill's aggressive abrasion resistance;

◆ High-quality PDC composite sheet diameter, reduce diameter wear and increase the wear resistance stability of diameter.

| drill bit parameters | |

| Dimensions | 6 1/8'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 13 |

| Number of nozzles | 5 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 3-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 20-35 |

| Features: single row of teeth, five blade wings and five water eyes |

◆ Suitable for soft to medium hard formation, limestone sandstone shale...;

◆ The surface of the blade is welded with high-performance wear-resistant materials to enhance the wear resistance and erosion resistance of the drill bit;

◆ Reasonable configuration of high quality PDC composite sheet, optimization of tooth structure to improve the drill's aggressive abrasion resistance;

◆ High-quality arc PDC composite sheet diameter, reduce diameter wear and increase the wear resistance stability of diameter;

◆ Hydraulic structure optimization and bottom-hole flow field design are conducive to the migration of rock cuttings and anti-mud bag.

| drill bit parameters | |

| Dimensions | 6 1/8'' |

| Number of blade wings | 6 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 6 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 3-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 20-35 |

| Features: double row teeth six knife wing |

◆ Suitable for soft to medium hard formation, limestone sandstone shale...;

◆ The main cutting tooth adopts roof tooth design to increase the service life of the drill bit's offensive wear resistance and rock breaking ability;

◆ Two rows of shock-absorbing columns, shock absorption and anti-wear to enhance the stability of the drill bit;

◆ Widen the blade and increase the bit torque;

◆ High-quality composite sheet diameter, reduce diameter wear and increase the wear resistance stability of drill bit diameter.

| drill bit parameters | |

| Dimensions | 6 1/8'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 6 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 3-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 20-35 |

| Features: Axe-shaped tooth, five knife wings, six water eyes |

◆ Suitable for medium hard strata, limestone shale sandstone...;

◆ The main cutting tooth adopts axe tooth design to enhance the impact resistance and wear resistance of the drill bit and extend the life of the drill bit;

◆ The second row of auxiliary teeth widen the blade to protect the cutting teeth from premature wear to ensure the cutting stability of the drill bit, and widen the blade to increase the torque of the drill bit;

◆ Six water eye layout, optimize hydraulic structure, strengthen chip removal efficiency and reduce mud bag generation;

◆ High-quality composite sheet diameter, reduce diameter wear and increase the wear resistance stability of drill bit diameter.

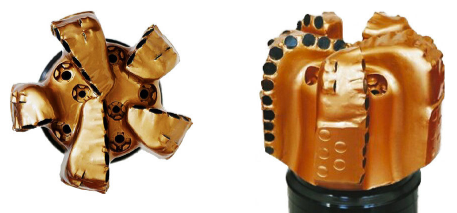

| drill bit parameters | |

| Dimensions | 8 1/2'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 13 |

| Number of nozzles | 6 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 20-36 |

| Features: double row teeth five knife wing six water eye |

◆ Suitable for soft to medium hard formation, limestone sandstone shale...;

◆ The surface of the blade is welded with high-performance wear-resistant materials to enhance the wear resistance and erosion resistance of the drill bit;

◆ Two rows of shock-absorbing columns, shock absorption and anti-wear to enhance the stability of the drill bit;

◆ Widen the blade and increase the bit torque;

◆ High-quality composite sheet diameter, reduce diameter wear and increase the wear resistance stability of drill diameter;

◆ Hydraulic structure optimization and bottom-hole flow field design are conducive to the migration of rock cuttings and anti-mud bag.

| drill bit parameters | |

| Dimensions | 8 1/2'' |

| Number of blade wings | 8 |

| Main cutting tooth specification | 13 |

| Number of nozzles | 4 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 25-36 |

| Features: double row teeth eight blade four water eye |

◆ suitable for high compressive strength, abrasive in hard strata, limestone anhydrite dolomite sandstone...;

◆ The surface of the blade is welded with high-performance wear-resistant materials to enhance the wear resistance and erosion resistance of the drill bit;

◆ The anti-rotation design of the short parabolic shape structure of the deep spiral blade wing can greatly improve the mechanical drilling speed stability of the drill bit;

◆ Reasonable configuration of high quality PDC composite sheet, optimization of tooth structure to improve the drill's aggressive abrasion resistance;

The use of PDC composite sheet to lengthen the diameter, improve the lateral stability of the bit pressure resistance, reduce the lateral offset to improve the quality of the borehole;

◆ Hydraulic structure optimization and bottom-hole flow field design are conducive to the migration of rock cuttings and anti-mud bag.

| drill bit parameters | |

| Dimensions | 8 1/2'' |

| Number of blade wings | 3 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 6 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 20-35 |

| Features: double row roof tooth 13 blade wing 6 water eye |

◆ Suitable for soft to medium hard formation, limestone sandstone shale...;

◆ The main cutting tooth adopts roof tooth design to increase the service life of the drill bit's offensive wear resistance and rock breaking ability;

◆ Two rows of shock-absorbing columns, shock absorption and anti-wear to enhance the stability of the drill bit;

◆ Widen the blade and increase the bit torque;

◆ High-quality composite sheet diameter, reduce diameter wear and increase the wear resistance stability of drill bit diameter.

| drill bit parameters | |

| Dimensions | 8 1/2'' |

| Number of blade wings | 4 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 6 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 25-36 |

| Features: double row teeth four blade wing six water eye |

◆ Suitable for medium and soft strata, clay rock shale limestone...;

◆ The surface of the blade is welded with high-performance wear-resistant materials to enhance the wear resistance and erosion resistance of the drill bit;

◆ The anti-rotation design of parabolic shape structure in deep spiral blade wing can greatly improve the mechanical drilling speed stability of the drill bit;

◆ Reasonable configuration of high quality PDC composite sheet, optimization of tooth structure to improve the drill's aggressive abrasion resistance;

The use of PDC composite sheet to strengthen the diameter, reduce the wear of the rock to the diameter, increase the wear resistance stability of the diameter to improve the service life of the drill bit;

◆ Hydraulic structure optimization and bottom-hole flow field design are conducive to the migration of rock cuttings and anti-mud bag.

| drill bit parameters | |

| Dimensions | 8 1/2'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 7 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 25-36 |

| Features: Double-row teeth, five blade wings, seven water eyes |

◆ suitable for high compressive strength, abrasive in soft strata, limestone clay rock shale...;

◆ The surface of the blade is welded with high-performance wear-resistant materials to enhance the wear resistance and erosion resistance of the drill bit;

◆ The anti-rotation design of parabolic shape structure in deep spiral blade wing can greatly improve the mechanical drilling speed stability of the drill bit;

◆ Reasonable configuration of high quality PDC composite sheet, optimization of low-density cloth tooth structure, improve the drill bit offensive anti-grinding;

◆ Reasonably optimize the hydraulic structure, deepen the design of the waterway to improve the efficiency of chip removal.

| drill bit parameters | |

| Dimensions | 8 1/2'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 7 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 30-180 |

| Displacement | 45-80 |

| Features: Double-row teeth, five blade wings, seven water eyes |

◆ Suitable for soft to medium hard formation, limestone shale sandstone...;

◆ Double-row tooth wide cutter wing design, optimize the tooth distribution structure to improve the aggressiveness of the drill bit, reduce gauge wear, increase the torque of the drill bit, and increase the wear resistance stability of the drill bit gauge;

◆ Seven water holes layout, optimize hydraulic structure, strengthen chip removal efficiency and reduce mud bag generation.

| drill bit parameters | |

| Dimensions | 8 1/2'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 7 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 20-36 |

| Features: three rows of teeth conjoined with five blades and six water eyes |

◆ Suitable for medium hard to hard abrasive formation, sandstone limestone anhydrite dolomite...;

◆ The inner cone increases the limit tooth design to better control the depth of the drill bit into the formation during drilling and avoid the early wear of the composite sheet;

◆ The conjoined blade design enhances the torsional strength of the blade;

The use of PDC composite sheet to strengthen the diameter, reduce the wear of the rock to the diameter, increase the wear resistance stability of the diameter to improve the service life of the drill bit;

◆ Hydraulic structure optimization and bottom-hole flow field design are conducive to the migration of rock cuttings and anti-mud bag.

| drill bit parameters | |

| Dimensions | 8 1/2'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 7 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 25-36 |

| Features: Double-row teeth, five blade wings, seven water eyes |

◆ suitable for high compressive strength, abrasive in hard strata, mudstone, sandstone and other interlayer stratum...;

◆ Optimize the width of the blade, reasonably extend the gauge length to enhance the stability of the drill bit;

◆ The flat parabolic shape structure of the deep spiral blade wing enhances the bit aggressiveness and can be better used in the directional well section;

◆ Reasonable configuration of high quality PDC composite sheet high-density cloth teeth, optimize the cloth tooth structure to improve the drill's aggressive anti-grinding performance;

The use of PDC composite sheet to strengthen the diameter, reduce the wear of the rock to the diameter, increase the wear resistance stability of the diameter to improve the service life of the drill bit;

◆ Hydraulic structure optimization and bottom-hole flow field design are conducive to the cleaning and cooling of the drill bit and the anti-mud bag.

| drill bit parameters | |

| Dimensions | 8 1/2'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 6 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 25-36 |

| Features: double row teeth five knife wing six water eye |

◆ suitable for high compressive strength, abrasive in hard strata, limestone anhydrite dolomite sandstone...;

◆ The surface of the blade is welded with high-performance wear-resistant materials to enhance the wear resistance and erosion resistance of the drill bit;

◆ The anti-rotation design of the long parabolic shape structure of the deep blade wing can greatly improve the mechanical drilling speed stability of the drill bit;

◆ Reasonable configuration of high quality PDC composite sheet, optimization of tooth structure to improve the drill's aggressive abrasion resistance;

◆ High-quality arc PDC composite sheet diameter, reduce diameter wear and increase the wear resistance stability of diameter;

◆ Hydraulic structure optimization and bottom-hole flow field design are conducive to the migration of rock cuttings and anti-mud bag.

| drill bit parameters | |

| Dimensions | 8 1/2'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 7 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 25-36 |

| Features: three rows of teeth conjoined blade |

◆ suitable for high compressive strength, abrasive in hard strata, limestone anhydrite dolomite sandstone...;

◆ Three rows of teeth are connected to the blade, and the inner cone is designed to increase the limit teeth to avoid the early collapse of the composite sheet, so as to better control the depth of the drill bit into the formation. The connected blade design enhances the torsion resistance of the blade;

◆ High-quality composite sheet diameter, reduce diameter wear and increase the wear resistance stability of drill bit diameter.

| drill bit parameters | |

| Dimensions | 8 1/2'' |

| Number of blade wings | 6 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 6 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 25-36 |

| Features: double row teeth six knife wing six water eye |

◆ Suitable for high compressive strength, abrasive hard formation, limestone dolomite quartz sandstone..;

◆ Increase the thickness of the blade, expand the contact area between the blade and the well surface, and improve the wear resistance, stability and pressure resistance of the drill bit;

The use of PDC composite sheet to lengthen the diameter, improve the lateral stability of the bit pressure resistance, reduce the lateral offset to improve the quality of the borehole;

◆ Hydraulic structure optimization and bottom-hole flow field design are conducive to the migration of rock cuttings and anti-mud bag.

| drill bit parameters | |

| Dimensions | 8 1/2'' |

| Number of blade wings | 6 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 8 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 25-36 |

| Features: Double-row teeth, six knife wings and eight water eyes |

◆ suitable for high compressive strength, abrasive in hard strata, limestone anhydrite dolomite sandstone...;

◆ The inner cone increases the limit tooth design to better control the depth of the drill bit into the formation during drilling and avoid the early wear of the composite sheet;

The use of PDC composite sheet to strengthen the diameter, reduce the wear of the rock to the diameter, increase the wear resistance stability of the diameter to improve the service life of the drill bit;

◆ Hydraulic structure optimization and bottom-hole flow field design are conducive to the migration of rock cuttings and anti-mud bag.

| drill bit parameters | |

| Dimensions | 8 1/2'' |

| Number of blade wings | 6 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 8 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 25-36 |

| Features: double row teeth six knife wing |

◆ suitable for high compressive strength, abrasive in hard strata, limestone anhydrite dolomite sandstone...;

◆ Double-row teeth with sixteen blades, and the inner cone increases the design of limiting teeth to avoid the early collapse of the composite sheet and better control the depth of the drill bit into the formation;

◆ High-quality composite sheet diameter, reduce diameter wear and increase the wear resistance stability of drill bit diameter.

| drill bit parameters | |

| Dimensions | 8 1/2'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 19 |

| Number of nozzles | 7 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 25-36 |

| Features: triangular teeth, five knife wings, seven water eyes |

◆ Suitable for medium and soft strata, limestone clay rock shale...;

◆ Triangular tooth design, enhance the impact resistance and wear resistance of the composite sheet;

◆ High-quality composite sheet diameter, reduce diameter wear and increase the wear resistance stability of drill diameter;

◆ The auxiliary tooth position is added with damping teeth, and the anti-rotation design slows down the vibration during drilling, effectively protecting the cutting teeth and improving the service life of the drill bit.

Short

Short

| drill bit parameters | |

| Dimensions | 8 1/2'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 19 |

| Number of nozzles | 5 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 25-36 |

| Features: triangular teeth, five blades, five water eyes |

◆ Suitable for medium and soft strata, limestone clay rock shale...;

◆ 19mm large composite triangular teeth five blade design, improve the mechanical drilling speed to enhance the impact resistance and wear resistance of the composite sheet;

◆ High-quality composite sheet diameter, reduce diameter wear and increase the wear resistance stability of drill diameter;

◆ Five water eyes widen and deepen the waterway, optimize the hydraulic structure, strengthen the chip removal efficiency and reduce the generation of mud bags.

| drill bit parameters | |

| Dimensions | 8 1/2'' |

| Number of blade wings | 3 |

| Main cutting tooth specification | 19 |

| Number of nozzles | 5 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 25-36 |

| Features: double row teeth five knife wing six water eye |

◆ Suitable for soft stratum, clay rock sandstone shaping mudstone...;

◆ The surface of the blade is welded with high-performance wear-resistant materials to enhance the wear resistance and erosion resistance of the drill bit;

◆ The anti-rotation design of the long parabolic shape structure of the deep blade wing can greatly improve the mechanical drilling speed stability of the drill bit;

◆ Reasonable configuration of high quality PDC composite sheet, optimization of tooth structure to improve the drill's aggressive abrasion resistance;

The use of PDC composite sheet to strengthen the diameter, reduce the wear of the rock to the diameter, increase the wear resistance stability of the diameter to improve the service life of the drill bit;

◆ Hydraulic structure optimization and bottom-hole flow field design are conducive to the migration of rock cuttings and anti-mud bag.

| drill bit parameters | |

| Dimensions | 8 1/2'' |

| Number of blade wings | 4 |

| Main cutting tooth specification | 19 |

| Number of nozzles | 6 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 25-36 |

| Features: triangular teeth, four blades, six water eyes |

◆ Suitable for medium-soft formation, limestone clay layer shale...;

◆ The 19mm triangular tooth high-quality composite sheet has a diameter-preserving four-blade design, which improves the mechanical drilling speed, enhances the impact resistance and wear resistance of the composite sheet, reduces the diameter-preserving wear, and increases the wear resistance stability of the drill bit diameter-preserving;

◆ The inverted tooth design solves the problem of rotary lifting during drilling and reduces the risk of necking and unstable symmetry;

◆ Six water holes widen the waterway to reduce the generation of mud bags and improve the drilling speed.

| drill bit parameters | |

| Dimensions | 8 1/2'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 19 |

| Number of nozzles | 5 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 25-36 |

| Features: single row of teeth, five blade wings and five water eyes |

◆ Suitable for medium and soft strata, clay rock shale limestone...;

◆ The surface of the blade is welded with high-performance wear-resistant materials to enhance the wear resistance and erosion resistance of the drill bit;

◆ The anti-rotation design of the short parabolic shape structure of the deep cutter wing can balance the surface force area, which is beneficial to reduce the wear of the drill bit, improve the service life of the drill bit, and greatly improve the mechanical drilling speed stability of the drill bit;

◆ Reasonable configuration of high quality PDC composite sheet, optimization of tooth structure to improve the drill's aggressive abrasion resistance;

The use of PDC composite sheet to strengthen the diameter, reduce the wear of the rock to the diameter, increase the wear resistance stability of the diameter to improve the service life of the drill bit;

◆ Hydraulic structure optimization and bottom-hole flow field design are conducive to the migration of rock cuttings and anti-mud bag.

| drill bit parameters | |

| Dimensions | 8 3/4'' |

| Number of blade wings | 4 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 6 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 25-36 |

| Features: double row teeth four blade wing six water eye |

◆ Suitable for soft to medium hard formation, limestone sandstone shale...;

The main cutting tooth adopts Mitsubishi tooth design, which increases the service life of the drill bit's offensive wear resistance and rock breaking ability;

◆ The surface of the blade is welded with high-performance wear-resistant materials to enhance the wear resistance and erosion resistance of the drill bit;

◆ High-quality composite sheet diameter, reduce diameter wear and increase the wear resistance stability of drill diameter;

◆ Hydraulic structure optimization and bottom-hole flow field design are conducive to the migration of rock cuttings and anti-mud bag.

| drill bit parameters | |

| Dimensions | 8 3/4'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 6 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 30-180 |

| Displacement | 25-36 |

| Features: triangular teeth axe-shaped teeth five knife wings seven water eyes |

◆ Suitable for medium hard strata, limestone shale sandstone...;

◆ The 12 rows of shock-absorbing columns with inner cone axe teeth are widened by ten blades to enhance the aggressiveness of the drill bit, shock absorption and anti-wear to increase the stability torque of the drill bit, and the high-quality composite sheet guarantees the diameter to strengthen the wear resistance stability of the diameter;

◆ Seven water holes layout, optimize hydraulic structure, strengthen chip removal efficiency and reduce mud bag generation.

| drill bit parameters | |

| Dimensions | 8 1/2'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 7 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 30-180 |

| Displacement | 25-36 |

| Features: Axe-shaped teeth, five knife wings, seven water eyes |

◆ suitable for high compressive strength in hard strata, limestone anhydrite dolomite sandstone...;

◆ Axe-type tooth five-blade design crown short parabola design, optimize the tooth distribution structure to improve the aggressiveness and rock breaking ability of the drill bit, balance the surface force of the drill bit to reduce wear, and improve the drilling ability and service life of the drill bit in directional wells;

◆ Seven water holes layout, optimize hydraulic structure, strengthen chip removal efficiency and reduce mud bag generation.

| drill bit parameters | |

| Dimensions | 9'' |

| Number of blade wings | 6 |

| Main cutting tooth specification | 19 |

| Number of nozzles | 7 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 6-5/8''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 20-110 |

| Displacement | 40-55 |

| Features: double row teeth six knife wing seven water eye |

◆ Suitable for soft to medium hard formation, shale sandstone limestone...;

◆ The 19mm composite sheet has two rows of auxiliary teeth to protect the main cutting teeth from premature wear, ensure cutting stability, strengthen the stability of wear resistance and improve the mechanical drilling speed;

◆ Optimize the hydraulic mechanism, the layout of the water eye strengthens the chip removal efficiency and reduces the generation of mud bags.

| drill bit parameters | |

| Dimensions | 9 1/2'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 19 |

| Number of nozzles | 6 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 25-35 |

| Features: double row teeth five knife wing six water eye |

◆ Suitable for medium-soft formation, limestone sandstone shale...;

◆ The main cutting tooth adopts roof tooth design to increase the service life of the drill bit's offensive wear resistance and rock breaking ability;

◆ Two rows of shock-absorbing columns, shock absorption and anti-wear to enhance the stability of the drill bit;

◆ Widen the blade and increase the bit torque;

◆ High-quality composite sheet diameter, reduce diameter wear and increase the wear resistance stability of drill bit diameter.

| drill bit parameters | |

| Dimensions | 9 1/2'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 19 |

| Number of nozzles | 5 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 4-1/2''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 25-36 |

| Features: single row of teeth, five blade wings and five water eyes |

◆ Suitable for soft to medium hard formation, sandstone shale limestone...;

◆ The surface of the blade is welded with high-performance wear-resistant materials to enhance the wear resistance and erosion resistance of the drill bit;

◆ The anti-rotation design of the short parabolic shape structure of the deep cutter wing can balance the surface force area, which is beneficial to reduce the wear of the drill bit, improve the service life of the drill bit, and greatly improve the mechanical drilling speed stability of the drill bit;

◆ Reasonable configuration of high quality PDC composite sheet, optimization of tooth structure to improve the drill's aggressive abrasion resistance;

The use of PDC composite sheet to strengthen the diameter, reduce the wear of the rock to the diameter, increase the wear resistance stability of the diameter to improve the service life of the drill bit;

◆ Hydraulic structure optimization and bottom-hole flow field design are conducive to the migration of rock cuttings and anti-mud bag.

| drill bit parameters | |

| Dimensions | 9 1/2'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 19 |

| Number of nozzles | 6 |

| Gauge Length | 1.5''-3.5'' |

| Connecting buckle type | 6-5/8''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 20-110 |

| Displacement | 30-40 |

| Features: double row teeth five knife wing six water eye |

◆ Suitable for soft to medium hard formation, limestone sandstone shale...;

◆ The surface of the blade is welded with high-performance wear-resistant materials to enhance the wear resistance and erosion resistance of the drill bit;

◆ The anti-rotation design of the parabolic shape structure in the deep blade wing can greatly improve the aggressive anti-grinding of the drill bit and the mechanical drilling speed stability of the drill bit;

◆ Reasonable configuration of high quality PDC composite sheet, optimization of tooth structure to improve the drill's aggressive abrasion resistance;

The use of PDC composite sheet to strengthen the diameter, reduce the wear of the rock to the diameter, increase the wear resistance stability of the diameter to improve the service life of the drill bit;

◆ Hydraulic structure optimization and bottom-hole flow field design are conducive to the migration of rock cuttings and anti-mud bag.

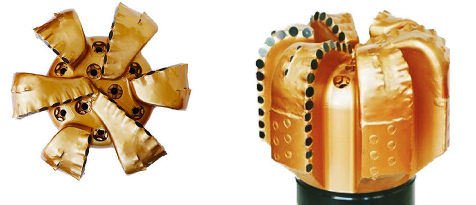

| drill bit parameters | |

| Dimensions | 12 1/4'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 7 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 6-5/8''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 10-100 |

| Displacement | 40-55 |

| Features: Double-row teeth, five blade wings, seven water eyes |

◆ Suitable for abrasive soft to medium hard formation, limestone sandstone shale...;

◆ The surface of the blade is welded with high-performance wear-resistant materials to enhance the wear resistance and erosion resistance of the drill bit;

◆ The anti-rotation design of the parabolic shape structure in the deep blade increases the depth of the blade, reduces the torque, and improves the drilling speed stability of the drill;

◆ Reasonable configuration of high quality PDC composite sheet, optimization of tooth structure to improve the drill's aggressive abrasion resistance;

The use of PDC composite sheet to strengthen the diameter, reduce the wear of the rock to the diameter, increase the wear resistance stability of the diameter to improve the service life of the drill bit;

◆ Hydraulic structure optimization and bottom-hole flow field design are conducive to the migration of rock cuttings and anti-mud bag.

| drill bit parameters | |

| Dimensions | 12 1/4'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 8 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 6-5/8''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 30-180 |

| Displacement | 45-80 |

| Features: three rows of teeth, five blades and eight water eyes |

◆ suitable for high compressive strength, abrasive strong hard formation, limestone anhydrite dolomite shale...;

The main cutting teeth, the use of triangular PDC composite cutting teeth, increase the impact of the drill bit wear resistance to extend the life of the drill bit;

◆ Two rows of auxiliary teeth and three rows of tapered teeth increase the cutting ability to attack and protect the main cutting teeth from premature wear;

◆ High-quality PDC composite sheet diameter, reduce the wear of the rock to the diameter, increase the wear resistance stability of the diameter;

◆ Hydraulic design optimization, so that the drill bit is fully cleaned and cooled.

| drill bit parameters | |

| Dimensions | 12 1/4'' |

| Number of blade wings | 6 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 9 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 6-5/8''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 30-180 |

| Displacement | 45-80 |

| Features: three rows of teeth, six blades and eight water eyes |

◆ suitable for high compressive strength, abrasive strong hard strata, limestone, anhydrite, dolomite, shale...;

The main cutting teeth, the use of triangular PDC composite cutting teeth, increase the impact of the drill bit wear resistance, extend the life of the drill bit;

◆ Two rows of auxiliary teeth and three rows of tapered teeth increase the cutting ability to attack and protect the main cutting teeth from premature wear;

◆ High-quality PDC composite sheet diameter, reduce the wear of the rock to the diameter, increase the wear resistance stability of the diameter;

◆ Hydraulic design optimization, so that the drill bit is fully cleaned and cooled.

| drill bit parameters | |

| Dimensions | 12 1/4'' |

| Number of blade wings | 6 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 9 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 6-5/8''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 20-110 |

| Displacement | 40-55 |

| Features: Double-row teeth, six knife wings, nine water eyes |

◆ Suitable for soft to medium hard strata with abrasiveness, shale, sandstone, chalk...;

◆ The surface of the blade is welded with high-performance wear-resistant materials to enhance the wear resistance and erosion resistance of the drill bit;

◆ Anti-rotation design of parabolic shape structure in deep blade, increase the thickness of blade, expand the contact area between blade and well surface, and improve the mechanical drilling speed, stability, grinding resistance and pressure resistance of drill bit;

◆ Reasonable configuration of high quality PDC composite sheet, optimization of tooth structure to improve the drill's aggressive abrasion resistance;

The use of PDC composite sheet to strengthen the diameter, reduce the wear of the rock to the diameter, increase the wear resistance stability of the diameter to improve the service life of the drill bit;

◆ Hydraulic structure optimization and bottom-hole flow field design are conducive to the migration of rock cuttings and anti-mud bag.

| drill bit parameters | |

| Dimensions | 12 1/4'' |

| Number of blade wings | 7 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 9 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 6-5/8''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 20-110 |

| Displacement | 40-55 |

| Features: double-row teeth, seven blades and eight water eyes |

◆ Suitable for soft to medium hard strata, limestone, anhydrite, dolomite, shale...;

The main cutting teeth, the use of triangular PDC composite cutting teeth, increase the impact of the drill bit wear resistance to extend the life of the drill bit;

◆ Two rows of bevel teeth increase the stability of the drill bit and protect the main cutting teeth from premature wear;

◆ Hydraulic design optimization, so that the drill bit is fully cleaned and cooled.

| drill bit parameters | |

| Dimensions | 12 1/4'' |

| Number of blade wings | 8 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 12 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 6-5/8''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 20-110 |

| Displacement | 40-55 |

| Features: double row teeth eight blade wing twelve water eye |

◆ Suitable for soft to medium hard formation, limestone, sandstone, shale...;

◆ The main cutting tooth adopts roof tooth design to increase the service life of the drill bit's offensive wear resistance and rock breaking ability;

◆ Two rows of shock-absorbing columns, shock absorption and anti-wear to enhance the stability of the drill bit;

◆ Widen the blade and increase the bit torque;

◆ High-quality composite sheet diameter, reduce diameter wear and increase the wear resistance stability of drill bit diameter.

| drill bit parameters | |

| Dimensions | 12 1/4'' |

| Number of blade wings | 4 |

| Main cutting tooth specification | 19 |

| Number of nozzles | 6 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 6-5/8''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 20-110 |

| Displacement | 40-55 |

| Features: triangular teeth, four blades, six water eyes |

◆ Suitable for medium and soft strata, limestone, clay rock, shale...;

◆ 19mm triangular tooth composite sheet keeps diameter of 14 blades, enhances the impact resistance and wear resistance of the composite sheet, effectively improves the mechanical drilling speed, strengthens the stability of diameter and wear resistance;

◆ Large inner cone short parabolic design, effectively improve the drilling speed.

| drill bit parameters | |

| Dimensions | 16'' |

| Number of blade wings | 7 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 10 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 6-5/8''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 30-180 |

| Displacement | 45-70 |

| Feature: Seven blade wing deepens waterway |

◆ suitable for high compressive strength, abrasive in hard strata, limestone, anhydrite, dolomite, sandstone...;

The tapered teeth, improve the drill bit offensive buffer, protect the cutting teeth to improve the stability of the drill bit service life;

◆ Seven blades deepen the waterway and improve the cutting ability and chip removal ability.

| drill bit parameters | |

| Dimensions | 17 1/2'' |

| Number of blade wings | 6 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 9 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 7-5/8''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 30-180 |

| Displacement | 45-70 |

| Features: single row of teeth, six blades, nine water eyes |

◆ Suitable for soft to medium hard strata, shale, sandstone, chalk...;

◆ The surface of the blade is welded with high-performance wear-resistant materials to enhance the wear resistance and erosion resistance of the drill bit;

◆ The anti-rotation design of the long parabolic shape structure of the deep blade increases the depth of the blade, reduces the torque, and improves the drilling speed stability of the drill;

◆ Reasonable configuration of high quality PDC composite sheet, increase the density of cloth teeth to improve the offensive abrasion resistance of the drill bit;

◆ High-quality arc PDC composite sheet diameter, reduce diameter wear and increase the wear resistance stability of diameter;

The damping teeth, slow down the vibration of the drill bit in drilling, improve the stability of the drill bit life;

◆ Hydraulic structure optimization, bottom-hole flow field design is conducive to the migration of rock cuttings and anti-mud bag, increase the number of nozzles to optimize the drill bit hydraulic circulation system, balance fluid flow is conducive to cooling cutting teeth to reduce drill bit erosion.

| drill bit parameters | |

| Dimensions | 17 1/2'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 19 |

| Number of nozzles | 5 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 7-5/8''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 30-180 |

| Displacement | 45-80 |

| Features: single row teeth five eyes waterway |

◆ Suitable for medium and soft strata, clay rock, shale, limestone...;

◆ High-quality PDC composite sheet diameter, reduce diameter wear and increase the wear resistance stability of diameter;

The spiral blade ten shock-absorbing column, effectively protect the cutting teeth, improve the stability of the drill bit and effectively control the cutting depth;

◆ Large waterway design, reduce mud bag to improve drilling speed.

| drill bit parameters | |

| Dimensions | 17 1/2'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 19 |

| Number of nozzles | 7 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 6-5/8''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 30-180 |

| Displacement | 45-80 |

| Features: double row tooth spiral blade wing seven eyes waterway |

◆ Suitable for soft to medium hard strata, limestone, anhydrite, dolomite, shale...;

◆ High-quality PDC composite sheet diameter, reduce diameter wear and increase the wear resistance stability of diameter;

The spiral blade ten shock-absorbing column, effectively protect the cutting teeth, improve the stability of the drill bit and effectively control the cutting depth;

◆ Large waterway design, reduce mud bag to improve drilling speed.

| drill bit parameters | |

| Dimensions | 17 1/2'' |

| Number of blade wings | 5 |

| Main cutting tooth specification | 19 |

| Number of nozzles | 7 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 6-5/8''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 20-110 |

| Displacement | 40-55 |

| Features: single row of teeth, five blade wings, seven water eyes |

◆ Suitable for soft to medium hard strata, shale, sandstone, chalk...;

◆ The surface of the blade is welded with high-performance wear-resistant materials to enhance the wear resistance and erosion resistance of the drill bit;

◆ The anti-rotation design of the long parabolic shape structure of the deep spiral blade increases the depth of the blade and reduces the torque. It improves the drilling speed stability of the drill;

◆ Reasonable configuration of high quality PDC composite sheet, increase the density of cloth teeth to improve the offensive abrasion resistance of the drill bit;

◆ High-quality arc PDC composite sheet diameter, reduce diameter wear and increase the wear resistance stability of diameter;

The damping teeth, slow down the vibration of the drill bit in drilling, improve the stability of the drill bit life;

Hydraulic structure optimization, increase the area of the flow channel to balance fluid flow, bottom flow field design is conducive to the migration of cuttings and anti-mud bag.

| drill bit parameters | |

| Dimensions | 26'' |

| Number of blade wings | 7 |

| Main cutting tooth specification | 16 |

| Number of nozzles | 10 |

| Gauge Length | 2''-3.5'' |

| Connecting buckle type | 7-5/8''API REG |

| recommend drill bit parameters | |

| Speed | 60-250 |

| Weight on Bit | 30-180 |

| Displacement | 60-100 |

| Features: double row teeth seven blade wing |

◆ Suitable for medium hard formation, shale, sandstone, chalk...;

The main cutting teeth, the use of triangular PDC composite cutting teeth, increase the impact of the drill bit wear resistance to extend the life of the drill bit;

◆ Two rows of tapered teeth, shock absorption and wear resistance, increase the offensive stability of the drill bit, and protect the main cutting teeth from premature wear;

◆ Widen the blade and increase the torque of the drill bit.

Online consultation

Related Products