Welcome to the official website of Guizhou Fulaimei Drilling Equipment Co., Ltd!

Contact Phone:13968981314

the

Key words:

.

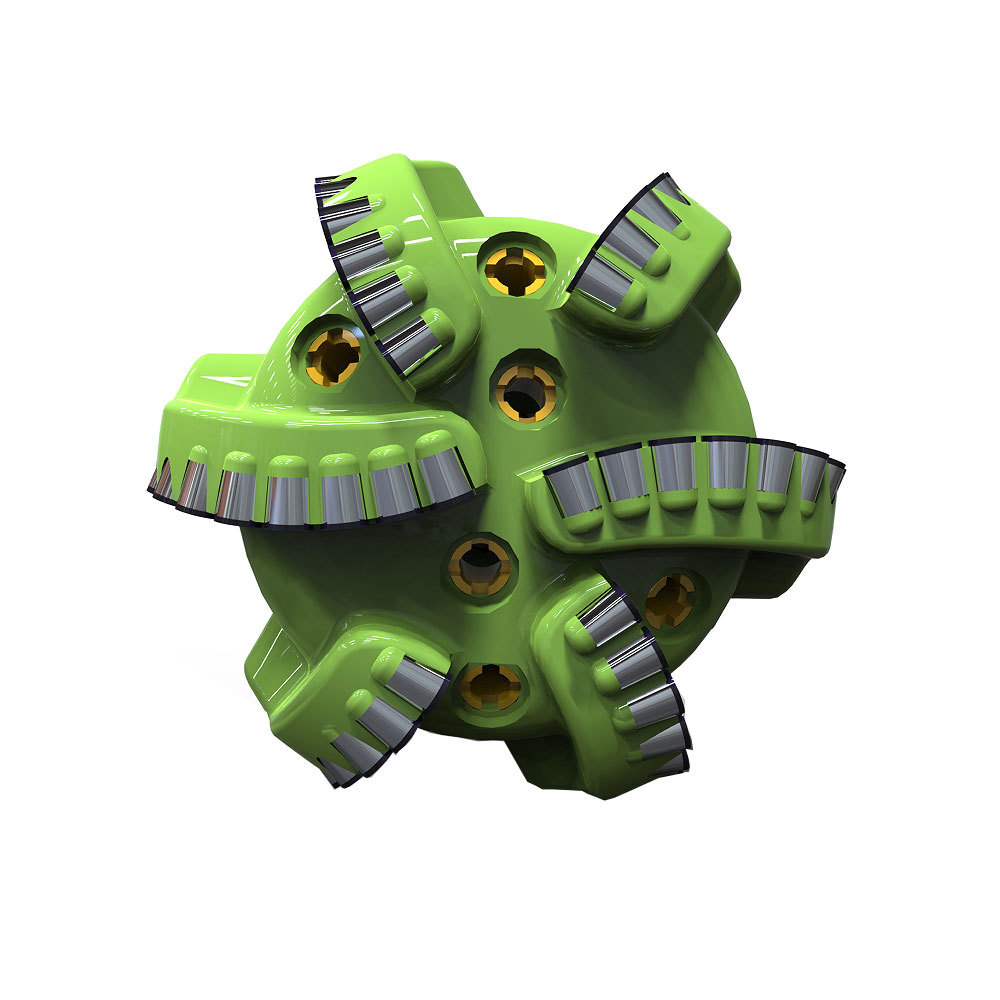

According to the geological conditions and requirements, PDC bit has many types, such as ordinary type, super type and high strength type. Among them, super strong and high strength drill bits may use more high quality blades or diamond blades to improve drilling speed and wear resistance.

Key words:

Cone bit is widely used in oil drilling, geological exploration, geotechnical engineering, building foundation construction and other fields. In the gravel layer and limestone formation, the cone bit has high drilling efficiency and good well quality, which can greatly reduce the construction drilling cost.

Cone bit is widely used in oil drilling, geological exploration, geotechnical engineering, building foundation construction and other fields. In the gravel layer and limestone formation, the cone bit has high drilling efficiency and good well quality, which can greatly reduce the construction drilling cost.

The cone bit uses the rotation of the cone (or gear) to break the rock and achieve the purpose of drilling. It is mainly composed of drill body, cone, bearing and nozzle. According to different uses and models, it may also contain auxiliary parts such as sealing and bearing lubrication. Roller bit plays an important role in petroleum, geological drilling and various geotechnical engineering fields.

Oil drill bit is the core equipment in oil drilling operation, and its working performance directly affects the drilling quality, drilling efficiency and drilling cost. Oil bit design is mostly based on practical experience, combined with the method of trial and error, through repeated design and calculation to improve. In order to improve the design quality and efficiency, it is necessary to develop the CAD system of oil drill bit to realize parametric drawing.

Key words:

Oil drill bit is the core equipment in oil drilling operation, and its working performance directly affects the drilling quality, drilling efficiency and drilling cost. Oil bit design is mostly based on practical experience, combined with the method of trial and error, through repeated design and calculation to improve. In order to improve the design quality and efficiency, it is necessary to develop the CAD system of oil drill bit to realize parametric drawing.

Key words:

Products

News